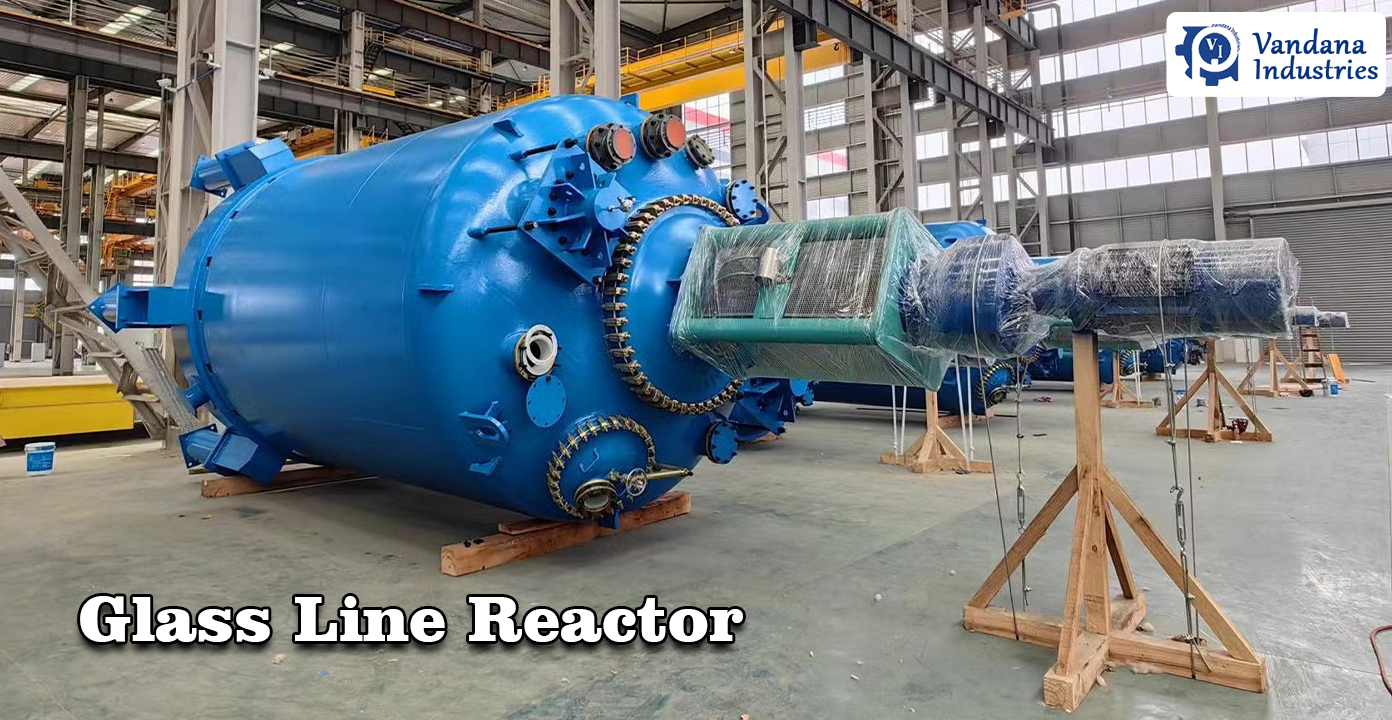

In industrial chemical processing, a Glass Line Reactor serves as one of the most reliable and durable vessels for reaction, mixing, and synthesis of chemicals. Designed with precision and engineered for resistance, these reactors combine the mechanical strength of steel with the corrosion resistance of glass. Vandana Industries, a prominent Manufacturer and Exporter, has earned recognition for supplying technically superior Glass Lined Reactors that meet the rigorous demands of industries like pharmaceuticals, petrochemicals, dyes, and specialty chemicals.

The construction of a glass line reactor involves fusing a high-quality glass layer to a robust steel substrate. This fusion results in a chemically inert and mechanically strong vessel capable of enduring both acidic and alkaline reactions under varying pressure and temperature conditions.

The Glass Line Reactor is constructed through a specialized enameling process where a borosilicate glass lining is bonded to the steel shell. This ensures a smooth, non-porous, and highly resistant internal surface. Each reactor designed by Vandana Industries undergoes controlled heat treatment cycles to create a strong interfacial bond between the glass and the metal.

The outer shell is fabricated using mild steel or carbon steel, depending on the application. The inner glass lining, typically 2–2.5 mm thick, provides resistance to a wide range of corrosive chemicals. The jacket design facilitates efficient heat transfer for exothermic or endothermic reactions, maintaining uniform temperature throughout the process.

Each unit produced by Vandana Industries is tested for durability, uniform coating, and thermal shock resistance. This ensures the reactor’s ability to operate in diverse chemical processing environments.

The fusion of glass and steel creates a unique composite structure that offers the best of both materials. The steel body provides strength to withstand internal pressure, while the glass lining offers chemical inertness and corrosion resistance.

These features make Glass Lined Reactors ideal for processes involving sensitive, corrosive, or high-purity chemical reactions.

From a mechanical perspective, Vandana Industries’ Glass Line Reactors are designed to balance internal pressure, mechanical stress, and temperature fluctuations. The steel shell maintains rigidity, while the enamel coating prevents corrosion.

Thermal performance is enhanced through efficient jacketed heating and cooling systems, allowing precise temperature control during reactions. The reactor design minimizes heat loss and ensures rapid response to thermal variations. Testing confirms the reactor’s ability to handle temperature gradients up to 120°C without cracking or delamination.

Vandana Industries, as a reliable Manufacturer and Exporter, offers design customization to meet varied process requirements. Reactors can be configured for batch or continuous operations with specialized fittings such as baffles, dip pipes, sight glasses, and temperature sensors.

Applications include:

Every configuration is engineered to enhance performance, safety, and ease of maintenance, making these reactors suitable for multipurpose plant environments.

To maintain international quality benchmarks, Vandana Industries conducts multiple stages of inspection during fabrication. Key tests include:

Each reactor comes with an inspection certificate detailing mechanical, electrical, and coating parameters. This ensures consistent product quality and operational reliability.

Safety is a major design principle in all Glass Lined Reactors manufactured by Vandana Industries. Every unit includes robust pressure relief mechanisms, anti-corrosive fittings, and precisely calibrated mechanical seals to prevent leakage.

Maintenance procedures are simplified due to the non-stick nature of the glass surface. Routine visual inspections and spark tests are sufficient to confirm the coating’s integrity. Operators benefit from extended service intervals and reduced downtime compared to conventional reactors.

Modern manufacturing facilities demand seamless integration between equipment and digital control systems. Vandana Industries designs its Glass Line Reactors to be compatible with automated process control systems, enabling remote monitoring of temperature, pressure, and agitation speed.

This automation compatibility enhances process accuracy, repeatability, and safety. It also allows integration with supervisory control and data acquisition (SCADA) systems, facilitating predictive maintenance and energy-efficient operation.

When compared to stainless steel or mild steel reactors, Glass Line Reactors deliver superior performance in chemical resistance and product purity. Stainless steel reactors, though robust, are prone to corrosion in acidic conditions. In contrast, the glass lining remains unaffected even by strong mineral acids like hydrochloric and sulfuric acid.

Additionally, glass line reactors eliminate the need for expensive corrosion inhibitors and surface coatings. This advantage significantly reduces operating costs over time and ensures consistent product yield and quality.

In industries where chemical resistance, purity, and durability are paramount, the Glass Line Reactor stands as a benchmark of engineering excellence. Vandana Industries, a leading Manufacturer and Exporter, continues to refine and innovate its reactor designs to meet global process requirements. By combining precision engineering with stringent quality control, the company delivers reactors that are efficient, safe, and long-lasting.

From laboratory-scale models to industrial-size installations, each Glass Lined Reactor embodies technical sophistication and structural integrity, ensuring dependable performance across diverse chemical applications.

Q1. What is the main advantage of using a Glass Line Reactor?

It provides high corrosion resistance and maintains product purity during chemical reactions.

Q2. What industries commonly use Glass Lined Reactors?

Pharmaceutical, petrochemical, chemical, and agrochemical industries widely use them.

Q3. How does the glass lining improve durability?

The enamel layer protects the steel body from corrosive materials and temperature fluctuations.

Q4. Are Glass Line Reactors suitable for high-pressure operations

Yes, depending on the design, they can safely handle pressures up to 6 kg/cm².

Q5. Can these reactors be integrated with digital control systems?

Yes, modern reactors by Vandana Industries are automation-ready and compatible with advanced process control systems.